Lodi Energy Center

Lodi Energy Center

(click for details)

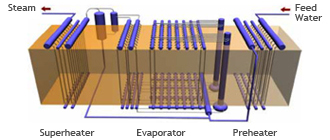

Once Through Steam Generators (OTSGs) are very similar to Heat Recovery Steam Generators (HRSGs) except for the actual process of steam generation in their evaporator section(s). N/E under a license from Siemens AG utilizes two single pass evaporator stages to evaporate and partially superheat the steam flow in the once through evaporator section. The primary stage evaporates the water to an intermediate steam quality and the secondary stage completes the evaporation and superheats the steam to a minimum level. In a typical system the HP EVAP is a OTSG while the IP and LP systems may be OTSGs or natural circulation with a steam drum. Outside of the actual evaporator design, the SHTRs, RHTRs, and ECONs of the HRSG and the OTSG are identical (though the actual heating surfaces may vary somewhat).

The OTSG has no steam drum since the water flow is 100% evaporated within the two evaporator passes. This requires somewhat better feedwater quality than the corresponding HRSG design including the use of condensate polishing. The water treatment regime within the systems may be very different since the OTSG must utilize all volatile treatment while the HRSG does not.

Since the thick HP steam drum has been eliminated in the OTSG design there are startup speed advantages. The startup of a HRSG is limited by the maximum allowable startup saturation temperature rise in the thick HP steam drum (typically in the 2-10°F/minute range). In the absence of the thick HP drum the OTSG can achieve higher startup ramp rates in the HP saturation temperature. This has the advantage of decreasing the overall elapsed OTSG startup time versus the corresponding HRSG for COLD startup times. Warm and hot startup times tend to be very similar for the OTSG and the HRSG.