Nooter/Eriksen is always available, providing technical support to our customers both virtually and with boots on the ground. The aftermarket team visits our customers regularly and is focused on providing value through technical recommendations we believe are in our customer’s best interest.

As part of our commitment to improving our customer’s bottom line, N/E is now offering our customers an innovative cooling tower water conditioning technology which has proven to optimize the use of chemicals, make-up water, and maintenance at your combined cycle power plant, refinery, or other industrial facilities.

In 2020 N/E contacted Hydropath Technology, the original patent holder for this cooling water conditioning technology. Hydropath Technology created and patented the technology in 1992 and has since sold over one million units worldwide from home size to large scale power plants. Established in 2010, HydroFLOW USA is the sole US distributor of these water conditioning devices and in 2020 N/E signed an agreement with HydroFLOW USA. N/E now licenses this technology under an agreement with HydroFLOW and can offer it directly to our customers.

The Hydropath/HydroFLOW technology has been validated in the past 10 years on domestic and international cooling towers at refineries, hospitals, government facilities, hotels, wastewater treatment plants, and other industrial facilities. Some examples include Nellis Air Force Base, a Phillips 66 Refinery, and Kaiser Permanente Hospital.

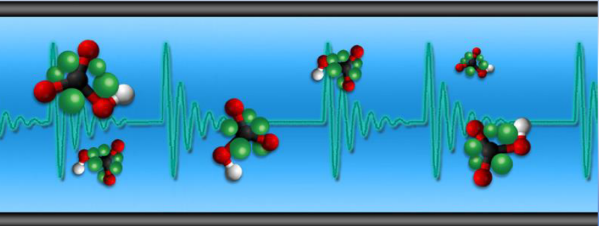

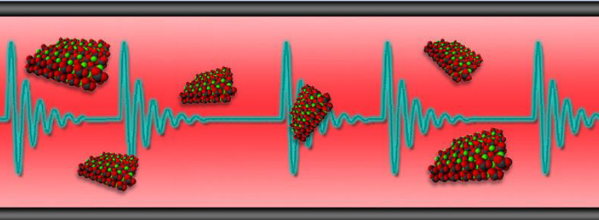

The HydroFLOW water conditioning device induces an electrical signal into the entire cooling water system which alters the arrangement of dissolved ions in solution causing them to cluster together in close proximity but not yet in solid/precipitated form. Changes in temperature or pressure that would normally result in solids scaling out on the piping and heat transfer surfaces now result in formation of sub-millimeter solids/precipitates within the flowing liquid.

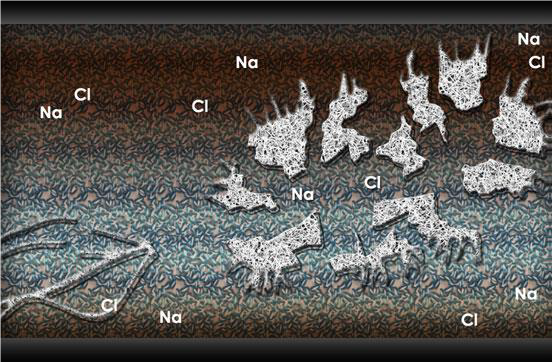

An additional benefit is that the device actively controls bacteria such as legionella, algae, and biofilm. The bacteria are electrically charged as they pass the device. The charged bacteria are quickly surrounded by pure water where osmosis begins to force water into the cell causing it to burst. These actions greatly reduce the ill effects of scale and biofouling. All of this occurs from the signal that is harmless to humans and the equipment in the cooling tower system.

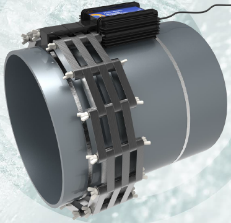

Installation of the HydroFLOW system is non-invasive and does not require any large machinery or welding. Below is an example of a HydroFLOW system installed on a 72” cooling tower pipe, along with a custom enclosure.

N/E understands this is a significant change from your current system. As such, we would like to come to your facility and meet with your management and technical teams to present this technology in more detail. N/E is very excited about this new technology and we believe the HydroFLOW device will increase your cooling tower performance while saving cost.