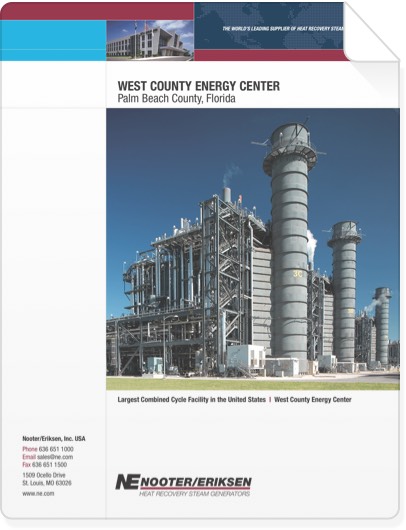

West County Energy Center

West County Energy Center

(click for details)

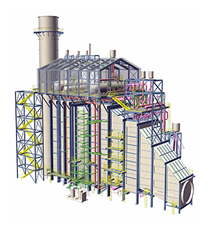

Nooter/Eriksen Heat Recovery Steam Generators are custom-designed to meet your project-specific needs. Our primary offering is a natural circulation design with horizontal exhaust flow and vertical tube design with internally insulated casing and structure. With many hundreds of HRSGs in operation around the world, Nooter/Eriksen has led the way in developing heat recovery technology behind combustion turbines as the equipment has grown in size and complexity. Innovative solutions are provided to meet the thermal performance, sound, and emissions requirements of your projects. We have the experience and expertise to design to a large variety of international codes and standards (e.g. EN, METI, ASME). N/E HRSGs are designed to address concerns of shipping restrictions, total installed costs (field constructability), reliability, and maintainability.

Lowest Installed Cost: Field construction solutions that cater to the project specific needs

N/E will offer an evaluated solution of in-land transportation restrictions and local field construction challenges to provide an optimal solution for your jobsite. Design details are developed to minimize field construction hours and all the components are maximized in size within shipping limitations. Options are available to further maximize shop fabrication. Components can be designed to address jobsite space or crane limitations. All consideration is given to minimize the total installed cost to provide the best value to our customers.

Reliability and Maintainability

N/E has many features dedicated to enhance HRSG reliability and reduce lifecycle costs.

- Spring hangers for coils minimize accumulated stresses in coils with high temperature differentials

- In heavy-walled components designs are implemented to minimize thicknesses and provide superior cyclic capability:

- HP Superheater and Reheater have stubbed tube to header connections

- Alternative materials for HP steam drums

- 2 Drum HP system to provide good retention with fast startup and high cycling operation

- Steam side bypass attemperation is used to control Reheat outlet steam temperature rather than spraywater desuperheating thereby eliminating any potential issues with liquid carryover or temperature quenching due to improper operation or equipment failure.

Innovation

N/E provides innovative solutions for common industry issues. We have patented systems which replace recirculation pumps to increase inlet water temperature to prevent cold end corrosion with an external heat exchanger.  We have high quality large bore casing drain penetrations to ease installation and prevent leakage. We have a trouble-free design for the blowdown piping and blowdown tank. Additionally, N/E can provide the heat balance solution to optimize the performance for the unique needs of your plant.

We have high quality large bore casing drain penetrations to ease installation and prevent leakage. We have a trouble-free design for the blowdown piping and blowdown tank. Additionally, N/E can provide the heat balance solution to optimize the performance for the unique needs of your plant.